The Critical Role of Chemical Containers

Importance of Proper Chemical Containment

In various industries such as manufacturing, automotive, and electronics, the use of chemicals is widespread. Chemicals play a crucial role in processes like production, cleaning, and treatment. However, they also pose significant risks if not stored and handled correctly. Choosing the right containers for chemicals is of utmost importance for several reasons.

Safety is the primary concern. Many chemicals are hazardous, with properties such as toxicity, flammability, and corrosiveness. Inadequate containers can lead to leaks, spills, or reactions that may cause harm to human health, including respiratory problems, skin burns, or even more severe injuries. For example, if a highly corrosive metal surface treatment agent leaks from a poorly - chosen container, it can damage equipment, infrastructure, and pose a threat to the safety of workers in the vicinity.

The quality of the chemicals themselves can be affected by improper containment. Chemicals can react with the material of the container, leading to degradation, loss of potency, or changes in chemical composition. This is especially true for metal surface treatment agents, which often need to maintain their specific chemical properties to be effective in treating metal surfaces. A change in the composition of a metal surface treatment agent due to an inappropriate container can result in poor surface treatment, leading to issues like reduced corrosion resistance or improper adhesion of coatings on metal surfaces.

Environmental protection is another key aspect. Chemical leaks or spills can contaminate soil, water sources, and the air, causing long - term damage to the ecosystem. By using proper containers, the risk of such environmental contamination can be minimized.

Scope of the Article

This article will cover a wide range of chemicals, including but not limited to acids, bases, solvents, and metal surface treatment agents. We will explore different types of containers, such as metal containers, plastic containers, glass containers, and composite containers, analyzing their suitability for various chemicals.

Special emphasis will be placed on metal surface treatment agents. These agents are used in a variety of industrial processes to clean, prepare, and protect metal surfaces. They can have diverse chemical compositions, including acidic, alkaline, and organic components. Understanding the appropriate containers for metal surface treatment agents is essential as they are commonly used in industries like metal manufacturing, automotive repair, and aerospace, where the quality of the metal surface treatment directly impacts the performance and durability of the final product. We will discuss how the chemical properties of metal surface treatment agents, such as their pH value, reactivity, and volatility, influence the choice of containers, and provide practical guidelines for selecting the most suitable containers in different industrial scenarios.

Key Considerations for Chemical Containers

Chemical Compatibility

Definition and Significance

Chemical compatibility refers to the ability of a container material to co - exist with a chemical without undergoing any chemical reactions that could lead to degradation of the container, contamination of the chemical, or the release of harmful substances. In the context of storing and handling chemicals, especially metal surface treatment agents, chemical compatibility is of utmost significance.

For metal surface treatment agents, which often have complex chemical compositions, ensuring compatibility with the container material is crucial. If a metal surface treatment agent reacts with the container, it can change the chemical properties of the agent. For example, if an acidic metal surface treatment agent is stored in a container made of a metal that can react with acids, the acid may corrode the metal, releasing metal ions into the treatment agent. This not only damages the container but also alters the composition of the treatment agent, potentially reducing its effectiveness in treating metal surfaces.

Moreover, an incompatible container - chemical combination can pose significant safety risks. Reactions between the chemical and the container material can lead to the release of toxic gases, heat, or even cause an explosion in extreme cases. Therefore, understanding the chemical compatibility of a metal surface treatment agent with different container materials is the first step in ensuring safe storage and handling.

Examples of Incompatible Chemical - Container Combinations

Acidic Chemicals and Metal Containers: Acidic metal surface treatment agents, such as those containing hydrochloric acid or sulfuric acid, are highly reactive with many metals. For instance, when hydrochloric acid - based metal surface treatment agents are stored in iron or steel containers, a chemical reaction occurs. The acid reacts with the iron, producing iron chloride and hydrogen gas. The reaction can be represented by the equation: \(Fe + 2HCl=FeCl_{2}+H_{2}\uparrow\). This not only weakens the structure of the container over time, leading to potential leaks, but also contaminates the metal surface treatment agent with iron ions, which can affect its performance.

Strong Oxidizers and Certain Plastic Containers: Some metal surface treatment agents with strong oxidizing properties, like those containing hydrogen peroxide or potassium permanganate, are incompatible with certain plastics. For example, low - density polyethylene (LDPE) plastic containers are not suitable for storing concentrated hydrogen peroxide solutions. Strong oxidizers can oxidize the plastic, causing it to become brittle, crack, or even decompose. This can result in the leakage of the metal surface treatment agent and potential safety hazards due to the reactivity of the oxidizer.

Physical Properties of Chemicals

Viscosity and Flow Characteristics

The viscosity and flow characteristics of chemicals, including metal surface treatment agents, play a significant role in determining the appropriate container.

Low - viscosity metal surface treatment agents flow easily. For these, containers with relatively small openings can be used for dispensing. For example, if a metal surface treatment agent has a viscosity similar to that of water, a container with a narrow - necked spout can be sufficient for controlled pouring. However, the interior surface of the container should be smooth to minimize resistance to flow. Materials like high - density polyethylene (HDPE) or glass, which have smooth surfaces, are good choices for storing low - viscosity metal surface treatment agents.

On the other hand, high - viscosity metal surface treatment agents, such as thick pastes used for surface coating and protection, require containers with larger openings. This allows for easier extraction of the agent. For example, a wide - mouthed plastic bucket might be suitable for a highly viscous metal surface treatment agent. Additionally, the container material should be such that the agent does not adhere to it strongly. Some special - purpose plastics with non - stick properties can be beneficial in such cases, as they ensure that most of the high - viscosity metal surface treatment agent can be removed from the container without leaving excessive residue.

Pressure and Temperature Sensitivity

Many chemicals, including metal surface treatment agents, are sensitive to pressure and temperature changes, and this has important implications for container selection.

Volatility and Pressure: Metal surface treatment agents that are volatile, such as those containing volatile organic solvents, can vaporize and increase the pressure inside a closed container. For example, if a metal surface treatment agent contains acetone as a solvent, which has a relatively high vapor pressure at room temperature, the container must be able to withstand the increased internal pressure. Rigid containers made of materials like thick - walled metal or high - strength plastic are required. These containers can prevent the build - up of excessive pressure from causing the container to burst. Additionally, containers may need to be equipped with pressure - relief valves to safely release excess pressure in case it exceeds the container's capacity.

Thermal Expansion: Chemicals, including metal surface treatment agents, can expand or contract with temperature changes. For instance, if a metal surface treatment agent is stored in a glass container and is exposed to a significant increase in temperature, the agent may expand more rapidly than the glass can accommodate. This can lead to the breakage of the glass container. Containers made of materials with similar coefficients of thermal expansion to the chemical they are storing are preferred. Some plastics, such as polypropylene (PP), have a relatively high tolerance to temperature changes and can be used for storing metal surface treatment agents that are moderately temperature - sensitive. For extremely temperature - sensitive metal surface treatment agents, specialized containers with thermal insulation features may be necessary to maintain a stable temperature inside the container.

Regulatory Requirements

Industry - Specific Standards

Chemical Industry: In the chemical industry, which often deals with a wide variety of metal surface treatment agents, there are strict standards for containers. For example, the American Society for Testing and Materials (ASTM) has standards for the design, construction, and performance of containers used to store and transport chemicals. For metal surface treatment agents that are classified as hazardous, containers must meet specific requirements regarding strength, corrosion resistance, and leak - proofing. These standards ensure that the containers can safely handle the chemicals during storage, transportation, and processing.

Pharmaceutical Industry: Although the pharmaceutical industry may not directly use metal surface treatment agents in the same way as the metal - manufacturing industries, when it comes to cleaning and maintaining metal equipment, the containers for related cleaning agents (which can be considered a type of metal surface treatment agent in this context) must comply with Good Manufacturing Practice (GMP) standards. GMP requires that containers be made of materials that are non - reactive, non - leaching, and easy to clean and sterilize. This ensures that the cleaning agents do not contaminate the pharmaceutical products during equipment cleaning processes.

Compliance with Safety Regulations

Compliance with safety regulations is essential when choosing containers for chemicals, including metal surface treatment agents. In the United States, the Occupational Safety and Health Administration (OSHA) has regulations regarding the storage and handling of hazardous chemicals. OSHA requires that containers for hazardous chemicals, such as corrosive or toxic metal surface treatment agents, be properly labeled with information about the chemical, its hazards, and any necessary safety precautions.

The containers must also be designed and maintained to prevent leaks and spills. For example, if a metal surface treatment agent is highly corrosive, the container must be made of a material that can resist corrosion over time, and it should be inspected regularly for any signs of wear or damage. In addition, storage areas for these chemicals must meet specific safety requirements, such as proper ventilation and separation from incompatible substances, all of which are related to the proper use of containers for safe chemical storage and handling. Failure to comply with these regulations can result in significant fines and legal consequences for companies, highlighting the importance of adhering to safety regulations in choosing and using chemical containers.

Types of Containers for Chemicals

Plastic Containers

Different Types of Plastics (e.g., HDPE, LDPE, PTFE)

Plastic containers are widely used in the storage and transportation of chemicals due to their lightweight, corrosion - resistance, and relatively low cost. There are several types of plastics commonly used for chemical containers, each with its own unique properties.

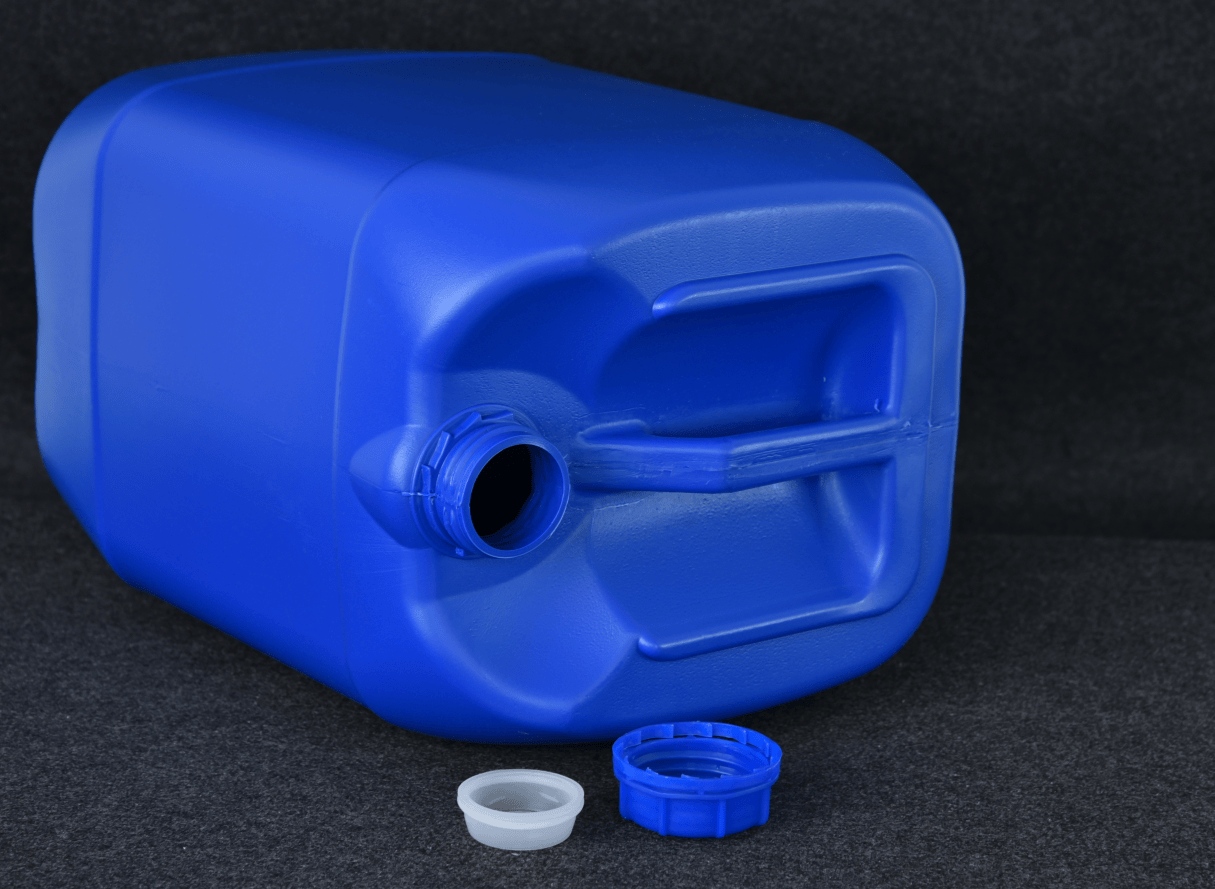

High - density polyethylene (HDPE) is a popular choice. It has a relatively high density, which contributes to its strength and durability. HDPE can withstand moderate temperatures and has good chemical resistance. For example, it can resist the corrosion of many acids and bases to a certain extent. Its melting point is around 130 - 137°C, and it can be used in a temperature range of -40°C to 90°C under normal conditions. HDPE is often used to make large - capacity containers such as drums for storing various industrial chemicals.

Low - density polyethylene (LDPE) is another common type. It is more flexible and has a lower density compared to HDPE. LDPE has excellent transparency, which is useful when it is necessary to visually inspect the contents. It also has good electrical insulation properties. However, it has a lower melting point, typically around 105 - 115°C, and is less heat - resistant than HDPE. LDPE is often used for making thin - walled containers, such as plastic bags and some small - scale chemical storage bottles.

Polytetrafluoroethylene (PTFE), also known as Teflon, is a high - performance plastic with extraordinary chemical stability. It can resist the attack of almost all chemicals, including strong acids, bases, and oxidants. PTFE has a very high melting point of around 327°C and can be used in a wide temperature range from -200°C to 260°C. Its low friction coefficient makes it suitable for applications where minimizing adhesion is important. Although PTFE is more expensive than HDPE and LDPE, its unique properties make it indispensable for storing highly reactive or corrosive chemicals.

Their Compatibility with Metal Surface Treatment Agents

The compatibility of different plastics with metal surface treatment agents varies.

HDPE is compatible with many metal surface treatment agents. For alkaline metal surface treatment agents, HDPE containers can often provide reliable storage. The chemical structure of HDPE is relatively stable in the presence of moderate - strength alkalis, and it does not react easily. For example, if a metal surface treatment agent contains sodium hydroxide as a main component for cleaning and degreasing metal surfaces, an HDPE container can safely store it without significant degradation or reaction. However, for some very strong oxidizing metal surface treatment agents, HDPE may not be the best choice, as long - term contact could potentially lead to oxidation of the plastic and a decrease in its structural integrity.

LDPE, due to its relatively soft and flexible nature, may not be suitable for storing highly concentrated or aggressive metal surface treatment agents. Some acidic metal surface treatment agents, especially those with high concentrations, can gradually penetrate and damage LDPE containers over time. For example, concentrated hydrochloric acid - based metal surface treatment agents can cause LDPE to become brittle and eventually leak. However, for less - reactive metal surface treatment agents with lower concentrations, LDPE containers can be used for short - term storage or in applications where cost - effectiveness is a major consideration.

PTFE, with its outstanding chemical resistance, is highly compatible with almost all types of metal surface treatment agents. Whether it is an acidic, alkaline, or highly reactive metal surface treatment agent, PTFE containers can provide a safe and reliable storage solution. For example, for metal surface treatment agents that contain a combination of strong acids and oxidants, which are used for complex surface etching and activation processes, PTFE containers are the preferred choice to ensure the integrity of the chemical and the safety of storage.

Composite Containers

Structure and Functionality

Composite containers are designed by combining two or more different materials to take advantage of the best properties of each. These containers typically consist of an inner liner made of a material with good chemical resistance, such as plastic (e.g., HDPE, PTFE), and an outer layer made of a stronger material, like fiber - reinforced plastics or metal.

The inner liner is in direct contact with the chemical and serves to prevent chemical leakage and ensure chemical compatibility. For example, if the chemical is a highly corrosive metal surface treatment agent, an HDPE or PTFE inner liner can resist the chemical's corrosive effects. The outer layer provides mechanical strength and protection against physical damage. Fiber - reinforced plastics, such as glass - fiber - reinforced plastic (GRP), are often used for the outer layer due to their high strength - to - weight ratio. They can withstand impacts, vibrations, and pressure, protecting the inner liner and the stored chemical. In some cases, a metal outer layer, like aluminum or steel, may be used for additional strength and durability, especially for applications where the container needs to be highly robust.

Composite containers also often have features like leak - proof seals and closures to further enhance their safety and functionality. These seals are designed to prevent any leakage of the stored chemical, even under challenging conditions such as transportation or long - term storage.

Application in Storing Metal Surface Treatment Agents

Composite containers are well - suited for storing metal surface treatment agents in various industrial scenarios.

In large - scale metal manufacturing plants, where metal surface treatment agents are used in large quantities, composite containers with metal outer layers can be used to store concentrated and hazardous metal surface treatment agents. For example, strong acidic metal surface treatment agents used for pickling metal surfaces are highly corrosive. A composite container with a PTFE inner liner and a steel outer layer can safely store these agents. The PTFE liner resists the acid's corrosion, while the steel outer layer provides the necessary strength to handle the large volume and weight of the chemical, as well as protection against external impacts during handling and storage.

For metal surface treatment agents that are sensitive to light or air, composite containers can be designed with additional protective features. For instance, some metal surface treatment agents used in the aerospace industry for treating high - performance metal components may react with oxygen or be degraded by light. A composite container with an opaque outer layer (such as a fiber - reinforced plastic with light - blocking additives) and an air - tight inner liner can prevent these unwanted reactions, ensuring the quality and effectiveness of the metal surface treatment agent.

In transportation, composite containers are also advantageous. Their lightweight yet strong construction makes them suitable for shipping metal surface treatment agents over long distances. For example, when metal surface treatment agents need to be transported from a manufacturing facility to a remote repair shop in the automotive industry, composite containers can withstand the vibrations and jolts during transportation while keeping the chemical safe and secure, reducing the risk of spills and ensuring the proper delivery of the metal surface treatment agent.

Future Trends in Chemical Containers

Development of New Materials

Emerging Materials with Enhanced Properties

The field of chemical containers is on the cusp of significant transformation with the emergence of new materials. One such category is advanced composite materials. These are engineered by combining two or more distinct materials at a macroscopic level, resulting in properties that are superior to those of the individual components. For example, carbon - fiber - reinforced polymers (CFRPs) are becoming increasingly popular. Carbon fibers offer high strength and stiffness, while polymers provide chemical resistance and formability. In the context of storing metal surface treatment agents, CFRP containers could potentially offer excellent protection. They are lightweight yet strong enough to withstand the rigors of handling and transportation, and their chemical - resistant polymer matrix can prevent reactions with the metal surface treatment agents.

Another exciting development is the advent of smart materials. Smart materials can change their properties in response to external stimuli such as temperature, pressure, or chemical exposure. Shape - memory alloys (SMAs) are a type of smart material. These alloys can "remember" their original shape and return to it when subjected to a certain temperature change. In the case of containers for metal surface treatment agents, SMAs could be used in the design of closures or seals. For instance, a SMA - based seal could expand or contract automatically in response to temperature variations, ensuring a tight seal at all times and preventing leaks of the metal surface treatment agent.

Their Potential Impact on Chemical Storage

New materials have the potential to revolutionize chemical storage in several ways. Firstly, in terms of safety, the enhanced properties of these materials can significantly reduce the risk of accidents. For example, the high - strength and chemical - resistant nature of advanced composite materials like CFRPs can minimize the chances of container failure due to corrosion or mechanical stress when storing metal surface treatment agents. This means fewer leaks and spills, protecting both human health and the environment.

Cost - effectiveness is another area where new materials can make a difference. Although some new materials may have a higher initial cost, their long - term benefits can lead to overall cost savings. For example, smart materials can improve the efficiency of chemical storage systems. A container with a smart - material - based self - adjusting seal may require less maintenance and replacement over time compared to traditional seals, reducing operational costs in the long run. Additionally, the use of lightweight materials such as CFRPs can lower transportation costs, as they reduce the weight of the containers and the chemicals they carry.

The performance of the stored chemicals can also be enhanced. New materials with better chemical compatibility can ensure that metal surface treatment agents maintain their integrity and effectiveness over longer periods. This is crucial as it can lead to improved quality in metal - treating processes, reducing the need for re - treatment and associated costs.

Innovations in Container Design

Improved Sealing Systems and Safety Features

Container design is also evolving to meet the increasing demands for safety and reliability. One of the key areas of innovation is in sealing systems. New sealing technologies are being developed to provide better protection against leaks. For example, there is a growing trend towards the use of multi - layer sealing systems. These systems consist of multiple layers of different materials, each contributing to the overall sealing performance. In a container for metal surface treatment agents, a multi - layer seal could include an inner layer of a highly chemical - resistant elastomer to prevent contact between the chemical and the outer layers, and an outer layer of a durable polymer to provide mechanical strength and protection against environmental factors.

Safety features are also being integrated into container designs. Some containers now come with built - in sensors that can detect leaks, changes in pressure, or temperature. For metal surface treatment agents, a pressure - sensitive sensor in the container can alert operators if the internal pressure is increasing due to a chemical reaction or a change in temperature. This allows for timely intervention, preventing potential accidents such as container rupture. Additionally, some containers are designed with emergency release valves that can safely release excess pressure in case of a dangerous build - up, further enhancing the safety of storing metal surface treatment agents.

Environmentally - Friendly Container Solutions

With the growing global focus on environmental protection, there is a strong trend towards the development of environmentally - friendly container solutions for chemicals, including metal surface treatment agents. One such solution is the use of recyclable materials. Many traditional plastic containers are now being designed to be more easily recyclable, with the development of new plastic formulations and manufacturing processes. For example, some plastics are being engineered to be compatible with existing recycling streams, making it easier to recycle containers used for metal surface treatment agents.

Another area of development is biodegradable containers. Biodegradable materials, such as certain types of bioplastics made from renewable resources like corn starch or cellulose, are being explored for use in chemical containers. These materials can break down naturally in the environment over time, reducing the problem of plastic waste. For less - hazardous metal surface treatment agents, biodegradable containers could be a viable option, providing a more sustainable alternative to traditional non - biodegradable containers.

The use of environmentally - friendly containers not only helps to reduce the environmental impact of chemical storage and disposal but also aligns with the growing corporate and consumer demand for sustainable practices. As more industries strive to meet environmental regulations and social responsibility goals, the adoption of these eco - friendly container solutions for metal surface treatment agents and other chemicals is likely to increase in the future.

Key Takeaways for Container Selection

Recap of Key Points

In the realm of chemical storage and handling, the choice of containers is a multifaceted decision. We have explored the crucial factors that must be considered when selecting containers for chemicals. Chemical compatibility stands as a cornerstone, as any reaction between the chemical and the container material can lead to disastrous consequences, such as container degradation, chemical contamination, and safety hazards. For example, the incompatibility between acidic metal surface treatment agents and metal containers can result in corrosion, leakage, and altered chemical properties of the treatment agent.

The physical properties of chemicals, including viscosity, flow characteristics, pressure, and temperature sensitivity, also play a significant role. Low - viscosity metal surface treatment agents require containers with smooth - interior surfaces for easy pouring, while high - viscosity agents need wide - mouthed containers. Chemicals that are sensitive to pressure and temperature changes demand containers that can withstand these variations, such as those equipped with pressure - relief valves or made of materials with suitable thermal expansion coefficients.

Regulatory requirements are non - negotiable. Industry - specific standards and safety regulations ensure that containers meet the necessary quality and safety criteria. For metal surface treatment agents, compliance with these regulations is essential to safeguard the well - being of workers, protect the environment, and maintain the integrity of industrial processes.

We have also examined the different types of containers available. Metal containers offer strength and heat - resistance but may have limitations in terms of chemical compatibility, especially with corrosive chemicals like some metal surface treatment agents. Plastic containers, with their various types such as HDPE, LDPE, and PTFE, provide options based on chemical resistance, flexibility, and cost. HDPE is suitable for many metal surface treatment agents, while PTFE is highly resistant to a wide range of chemicals. Glass containers are ideal for certain applications due to their transparency and chemical stability, and composite containers combine the advantages of multiple materials to provide enhanced protection for storing metal surface treatment agents.

Final Thoughts on the Importance of Right Container Selection

The correct selection of containers for chemicals, particularly metal surface treatment agents, is of paramount importance. It is not merely a matter of convenience but a critical aspect of ensuring the safety of personnel, the integrity of the chemicals, and the protection of the environment. In industrial settings, improper container selection can lead to costly accidents, production delays, and environmental pollution.

For example, a leakage of a metal surface treatment agent due to an inappropriate container can damage equipment, require extensive cleanup efforts, and potentially harm workers. On the other hand, choosing the right container can enhance the efficiency of industrial processes. By maintaining the chemical properties of metal surface treatment agents, the quality of metal surface treatments can be improved, leading to better - quality products in industries such as metal manufacturing, automotive, and aerospace.

As new materials and container designs continue to emerge, the future holds great promise for even safer and more efficient chemical storage. However, regardless of these advancements, the fundamental principles of chemical compatibility, consideration of physical properties, and compliance with regulations will always remain at the core of choosing the right containers for chemicals. It is incumbent upon industries and individuals handling chemicals to stay informed about the latest developments and best practices in chemical containment to ensure a safe and sustainable future.