Understanding Non-Caustic Powder Cleaners

Non-caustic powder cleaners represent a breakthrough in metal cleaning technology. Unlike traditional caustic cleaners that contain harsh alkaline substances, these innovative products use milder chemical compounds while maintaining powerful cleaning capabilities. The key difference lies in their pH levels - caustic cleaners often exceed pH 12, while non-caustic alternatives typically range between pH 8-10. This significant reduction in alkalinity makes them far safer for handling and application. The development of non-caustic formulas addresses growing environmental concerns and workplace safety regulations. By eliminating highly corrosive ingredients, these cleaners prevent metal damage while effectively removing contaminants. The aluminum and soft metals safe designation particularly benefits industries working with delicate alloys that traditional cleaners would quickly degrade.

How They Work Without Corrosion

The effectiveness of non-caustic powder cleaners stems from advanced chemistry rather than brute-force alkalinity. These formulations utilize specially selected surfactants and chelating agents that break down organic residues through micelle formation rather than chemical burning. The cleaning process involves three key stages: initial wetting where surfactants reduce surface tension, followed by soil suspension through encapsulation, and finally rinsing away contaminants. For aluminum and soft metals, the absence of caustic components means no surface etching or pitting occurs during cleaning. The pH-balanced formula ensures gentle yet thorough cleaning by targeting specific contaminant types without attacking the base metal. This method preserves surface finishes and dimensional accuracy, making it ideal for precision components. The non-caustic nature also allows for safer application in confined spaces and reduces protective equipment requirements.

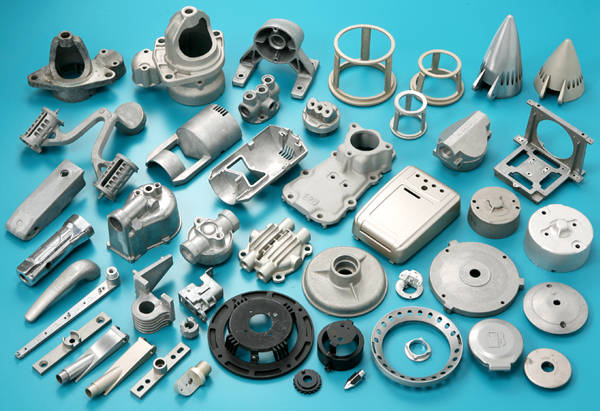

Benefits for Aluminum Components

Aluminum's unique properties make it particularly vulnerable to caustic cleaners. Its softness and tendency to form surface oxides require specialized care during cleaning. Non-caustic powder cleaners offer multiple advantages for aluminum applications. The gentle chemistry prevents surface etching that can lead to premature failure in mechanical components. For example, in automotive applications where aluminum parts experience high stress, preserving surface integrity is crucial for longevity. These cleaners also maintain the natural oxide layer that protects against corrosion, unlike caustic alternatives that strip this protective coating. The absence of aggressive chemicals means no hydrogen embrittlement risk, a common issue with caustic cleaners that can weaken aluminum alloys over time. Additionally, the safer handling properties reduce workplace hazards and allow for more frequent cleaning cycles without component degradation.

Advantages for Soft Metals

Soft metals like copper, brass, and magnesium share similar cleaning challenges with aluminum but require even greater care due to their lower hardness. Non-caustic powder cleaners excel in these applications by providing effective cleaning without surface damage. For copper components, which are often used in electrical applications, maintaining surface conductivity is critical - something caustic cleaners can compromise through surface roughening. Brass fittings and decorative elements benefit from the formulation's ability to remove tarnish without altering surface appearance. Magnesium alloys, which are increasingly used in aerospace applications, are particularly sensitive to caustic attack. The non-caustic approach prevents the formation of micro-cracks that can propagate under stress, ensuring structural integrity. The versatility of these cleaners across different soft metal types makes them invaluable in multi-material assemblies.

Environmental and Safety Considerations

The environmental profile of non-caustic powder cleaners represents a significant improvement over traditional options. The reduced alkalinity means these products are less harmful to aquatic life and require less stringent wastewater treatment. Safety benefits extend to the workplace as well - lower pH levels reduce skin irritation risks and eliminate the need for specialized protective equipment in many applications. The powder form itself offers advantages over liquid alternatives, including reduced shipping weight and volume, lowering transportation emissions. Spill containment is easier with powder formulations, and they typically have longer shelf lives due to their dry state. From a regulatory standpoint, these cleaners often fall under less restrictive categories, simplifying compliance efforts for manufacturers. The combination of environmental and safety benefits makes these cleaners a sustainable choice for industries aiming to reduce their ecological footprint.

Application Techniques for Optimal Results

Proper application of non-caustic powder cleaners is essential to maximize their effectiveness while maintaining safety. The cleaning process typically involves three key steps: preparation, application, and rinsing. For best results, components should be pre-rinsed to remove loose debris before applying the cleaner. The powder should be dissolved in water at the recommended concentration - usually between 2-5% by weight depending on soil severity. Temperature plays a crucial role in cleaning efficiency, with most formulations performing optimally between 120-160°F (49-71°C). Agitation methods should be carefully selected based on component sensitivity - soft metals may require gentle brushing or ultrasonic cleaning rather than high-pressure spray methods. Rinsing must be thorough to remove all traces of cleaner, as even non-caustic residues can cause issues if left on sensitive surfaces. Following these application guidelines ensures consistent cleaning results while protecting component integrity.

Comparing with Traditional Caustic Cleaners

When evaluating non-caustic powder cleaners against traditional caustic alternatives, several key differences emerge. Caustic cleaners often provide faster initial cleaning due to their aggressive chemistry, but this comes at the cost of surface damage and safety concerns. Non-caustic alternatives may require slightly longer contact times but offer superior results in terms of surface preservation. The total cost of ownership analysis favors non-caustic cleaners when considering waste disposal, worker safety, and component replacement costs. For example, in industries where aluminum components are repeatedly cleaned, the cumulative surface damage from caustic cleaners can lead to premature failure, offsetting any initial cost savings. The ability to use non-caustic cleaners on multi-material assemblies without segregation further enhances their value proposition. While caustic cleaners may still have niche applications, the trend is clearly shifting toward safer, more sustainable alternatives.

Industry-Specific Applications

Various industries have adopted non-caustic powder cleaners for their specific cleaning challenges. In automotive manufacturing, these cleaners are used for engine components, transmission parts, and aluminum body panels where surface finish preservation is critical. The aerospace industry benefits from their ability to clean magnesium and aluminum alloys without compromising structural integrity. Electronics manufacturers use them for printed circuit boards and connectors where residue-free cleaning is essential. In the medical device sector, these cleaners meet stringent cleanliness requirements while being compatible with implantable materials. Food processing equipment cleaning applications benefit from the non-toxic nature of these formulations. Each industry sector has unique requirements that non-caustic powder cleaners address through their versatile chemistry and gentle cleaning action.

Future Developments in Cleaning Technology

The field of non-caustic cleaning technology continues to evolve, with ongoing research focused on enhancing performance while further reducing environmental impact. Emerging innovations include biodegradable surfactants and green chemistry approaches that improve cleaning efficiency without relying on traditional alkaline compounds. Smart cleaning systems that adjust pH and temperature in real-time based on soil type are being developed to optimize cleaning cycles. The integration of nanotechnology offers potential for creating self-cleaning surfaces that reduce the need for frequent cleaning. As material science advances, cleaning formulations must adapt to new alloy compositions and surface treatments. The future of metal cleaning lies in solutions that provide excellent cleaning performance while being environmentally benign and safe for all metal types, including emerging lightweight alloys.